Hewlett-Packard LaserJet III

I recently repaired a 1990 vintage Hewlett-Packard LaserJet III. This printer seems like a very appropriate companion to the 386 server, which now functions as its print spooler. I bought the printer in 2003 but was only able to use it for a few months before I started experiencing frequent paper jams and hearing a horrible loud clicking noise. Smudges started to appear on printed pages.

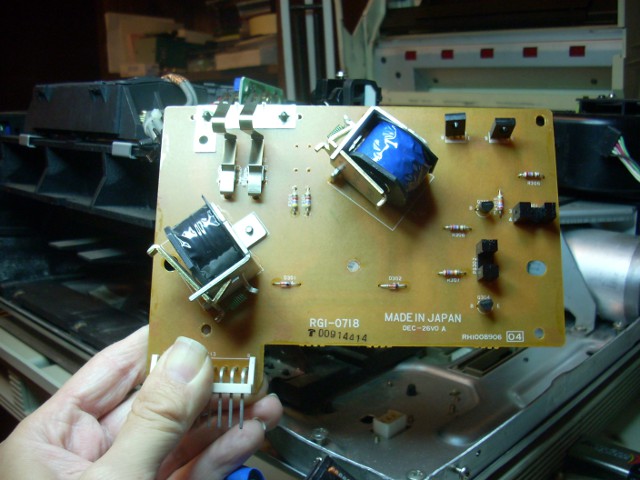

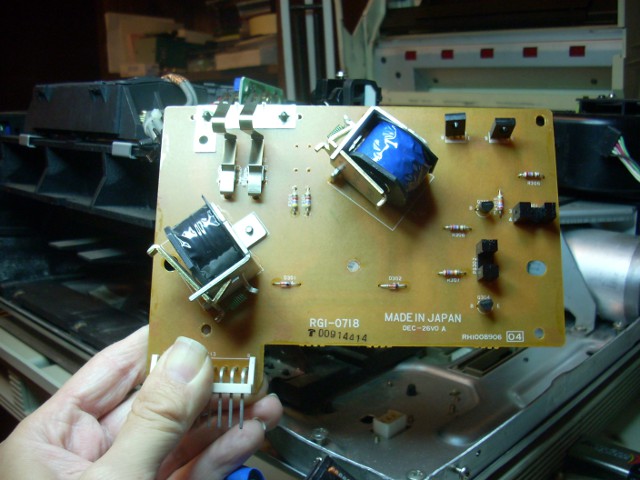

I first noted that the feed and transfer roller clutches did not reliably engage when the printer attempted to load paper. Small solenoids on the circuit board shown below control these clutches. The solenoids were functional, but the Darlington transistors driving them were questionable. Not having the original Japanese Darlingtons on hand, I used pairs of metal 2N2222A transistors, which have current handling capacities well in excess of that required by the solenoids. A less "redneck" parts substitution would have been a TIP120 Darlington. This is a TO-220 device that can be found for as little as $0.39 apiece.

Unfortunately, even with the feed roller clutch operating reliably, pickup of paper from the tray was still erratic. I was able to fix this by installing a "paper jam kit" consisting of a new roller tire and paper separator pad. In their old age, the old roller tire had become hard and smooth, and the separator pad had become sticky. The other rollers appear to be in good shape, although I am considering buying some spares to keep on hand if the price is right.

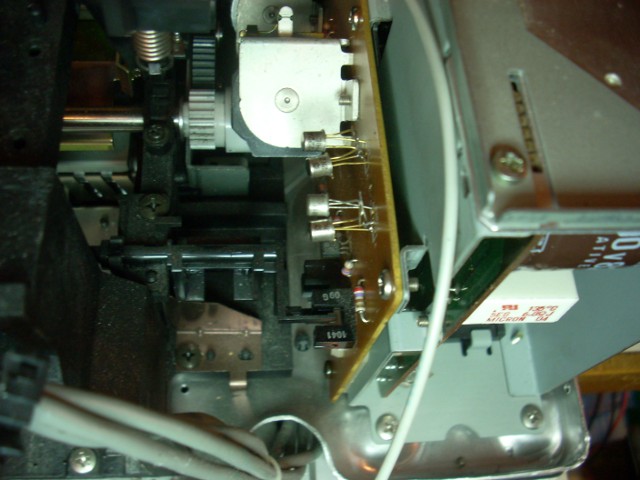

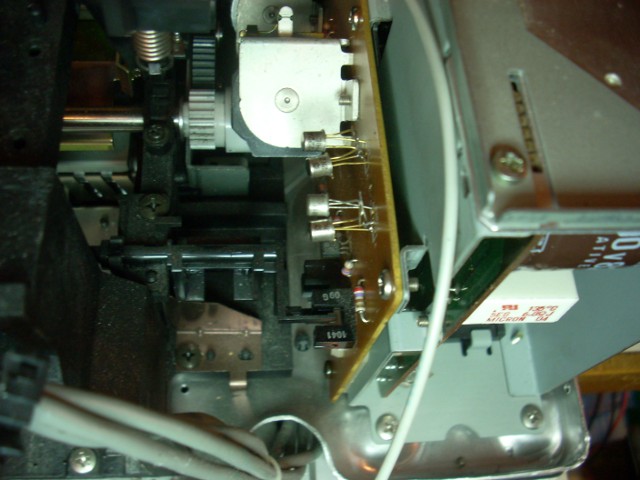

The plastic gears in laser printers are prone to becoming hard and brittle due to heat from the fuser. I noted that one of the fuser gears (see below) was showing signs of discoloration and wear. I was able to find an inexpensive maintenance kit online consisting of this gear, as well as the cotton pad that continually cleans the upper fuser roller. Installing the new gear did not stop the clicking noises, but changing the cotton pad eliminated the smudges. To maintain print quality, it is recommended that these cleaning pads be changed each time that a new toner cartridge is installed. Another reason that it is important to regularly change these pads is that a clean pad places less drag on the fuser drum, and this may help extend the life of the drive gears.

Eventually, I discovered that the loud clicking was due to a stripped gear in the transmission gear cluster. Shopping around online, I was able to find an unused new old stock gear cluster for about $20. Some of the gears in the old gear cluster, particularly the stripped one, had a gray color that may have been due to exposure to heat. The old gear cluster and dirty fuser cleaning pad are shown below, on the left. Next to that is the Laser Jet III, ready to print, once again (please pardon the messy bench).